What are the typical capacity and speed considerations for Industrial bucket elevators?

Capacity: The capacity of an

industrial bucket elevator is a crucial factor and is usually expressed in terms of the volume or weight of material that can be transported per unit of time. Capacities can vary widely depending on the size and design of the elevator, as well as the characteristics of the material being handled.

Speed: The speed of the bucket elevator is another important consideration. It refers to the rate at which the buckets or cups are lifted or lowered. The speed is typically measured in feet per minute (FPM) or meters per second (m/s).

Bucket Size and Spacing: The size and spacing of the buckets or cups on the elevator belt or chain also affect the capacity and speed. Larger buckets can handle more material per bucket load, increasing the overall capacity.

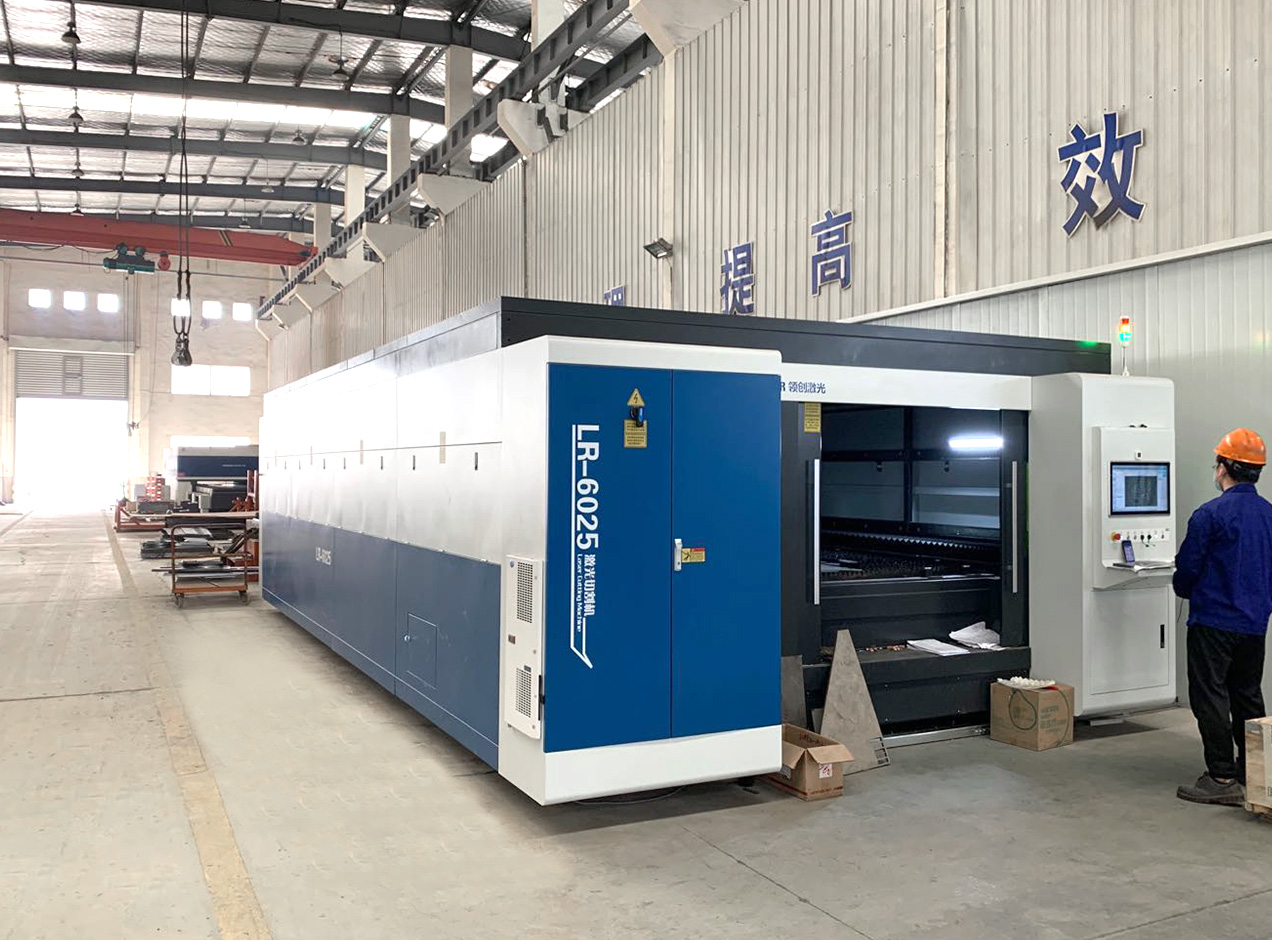

Motor Power and Drive System: The motor power and drive system of the bucket elevator should be selected based on the required capacity, speed, and the characteristics of the material being handled.

Safety Considerations: Industrial bucket elevators should comply with safety regulations and standards specific to the industry and region. Safety features such as emergency stops, guards, and monitoring systems should be incorporated to prevent accidents and protect personnel.

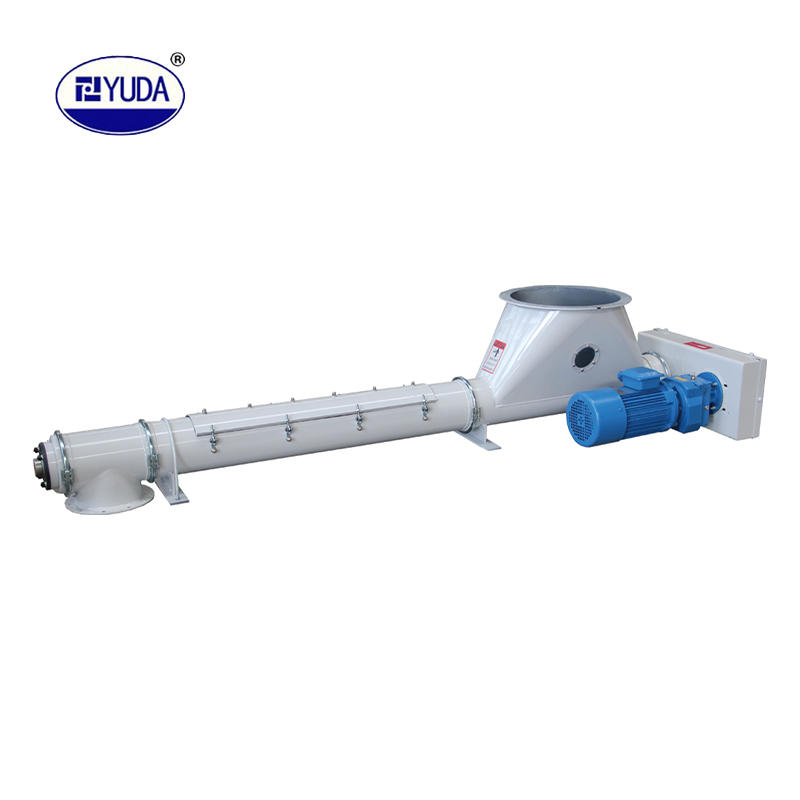

What are the key components of a Drag Chain Conveyors?

Drag chain conveyors are a type of mechanical conveying system that are commonly used to move bulk materials horizontally or at a slight incline. They consist of several key components, each playing a crucial role in the operation of the conveyor system. Here are the main components of a drag chain conveyor:

Chain: The chain is the primary component that carries the bulk material along the conveyor. It typically consists of a series of interconnected links or paddles, which are attached to the conveyor's drive mechanism. The chain is designed to withstand the load and abrasion from the material being conveyed.

Drive Mechanism: The drive mechanism is responsible for moving the chain and providing the necessary power to propel the material forward. It typically includes an electric motor, gearbox, and sprockets that engage with the chain. The drive mechanism can be located at one or both ends of the conveyor, depending on the system design.

Trough or Enclosure: The trough or enclosure serves as the housing for the chain and material being conveyed. It is usually made of durable materials such as steel and is designed to contain the bulk material and prevent spillage. The shape and size of the trough may vary depending on the specific application and material characteristics.

Drag Elements: The drag elements, often in the form of paddles or flights, are attached to the chain at regular intervals. They provide the necessary traction to move the bulk material along the conveyor. The design of the drag elements can vary to suit different materials and operating conditions.

Return System: A drag chain conveyor typically includes a return system that guides the chain back to the starting point after it has completed the conveying cycle. This system ensures proper tensioning of the chain and allows for continuous operation of the conveyor.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com