What are the essential spare parts for feed machines?

Augers/Screws: Augers or screws are used to transport and mix the feed ingredients within the machine. They are prone to wear and tear and may need replacement over time.

Belts: Feed machines often use belts to transfer power from the motor to various components. Belts can stretch, wear out, or break, so having spare belts of the correct size is important.

Bearings: Bearings are critical components that support the rotating parts of the feed machine. They can wear out due to continuous use, so having spare bearings of the appropriate size and type is necessary.

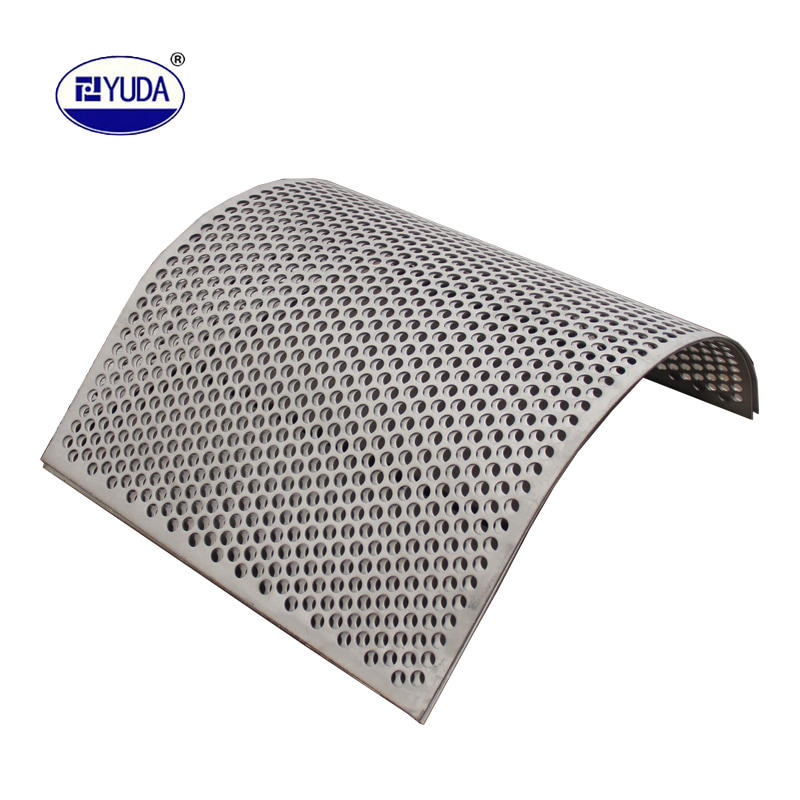

Screens/Sieves: Screens or sieves are used to separate and classify feed particles based on size. They can get clogged or damaged, so having spare screens or sieves in different mesh sizes is useful.

Hammers: Hammer mills are commonly used in feed processing, and their hammers can wear out or break due to the impact of grinding feed materials. Having spare hammers is essential for uninterrupted operation.

Knife Blades: Some feed machines, such as choppers or cutters, use knife blades to process or chop the feed. Knife blades can become dull or damaged and may require replacement.

Electrical Components: Feed machines may have electrical components such as motors, switches, relays, and control panels. Having spare electrical components can be helpful in case of failures or malfunctions.

Gaskets and Seals: Gaskets and seals are used to prevent leaks and maintain proper sealing in feed machines. They can degrade over time and may need replacement to ensure optimal performance.

Drive Shafts and Couplings: Feed machines with complex mechanisms may have drive shafts and couplings that transmit power between different parts of the machine. Spare drive shafts and couplings can be necessary in case of failures or accidents.

Wear Plates/Liners: Wear plates or liners are used in feed machines to protect the equipment from excessive wear caused by abrasive feed materials. These plates can wear out and should be replaced to maintain machine efficiency.

How frequently do different spare parts need to be replaced in feed machines?

Blades or Hammers: These components are commonly found in hammer mills or grinders used for grinding feed ingredients. The replacement frequency can range from a few weeks to several months, depending on the type of feed being processed, the grinding intensity, and the quality of the blades or hammers.

Screens or Sieves: Feed machines often incorporate screens or sieves to control the particle size of the feed. The replacement interval for these parts can vary widely based on factors such as feed composition, feed volume, and the screen's durability. It can range from a few months to a year or more.

Belts and Chains: Feed machines may utilize belts or chains for power transmission. The lifespan of these components can vary significantly, depending on factors like the machine's operating conditions, maintenance practices, and the quality of the belts or chains. Regular inspection and replacement as needed is recommended.

Bearings: Bearings are used in various rotating components of feed machines such as shafts and rollers. The replacement frequency for bearings can depend on factors like operating hours, maintenance practices, and the quality of the bearings themselves. Regular lubrication and monitoring can help extend their lifespan.

Augers or Conveyor Components: Augers and conveyor systems are commonly used for material handling in feed machines. The replacement interval for these components can depend on factors such as the material being conveyed, the operating conditions, and the quality of the components. Regular inspection and maintenance are crucial to identify wear and tear.

Electrical Components: Feed machines may have electrical components like motors, switches, and control panels. The lifespan of these parts can vary significantly based on usage, maintenance, and the quality of the electrical components. Repairs or replacements may be necessary in case of malfunctions or wear.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email:

Email: