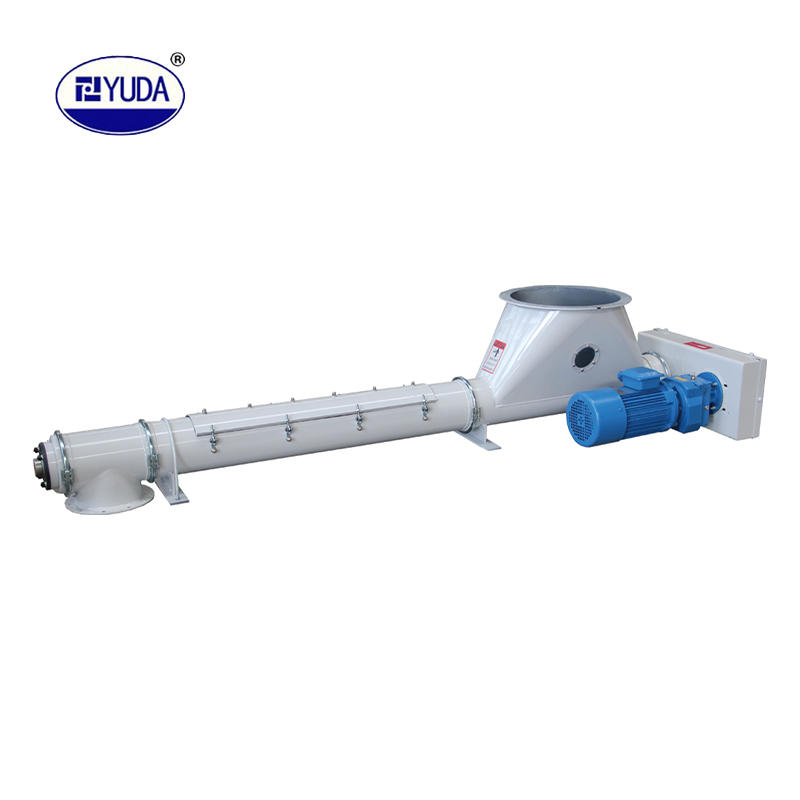

This series of hammer crusher can crush all kinds of granulated feed ingredients, such as corn, sorghum, wheat, beans, broken cake after class, and other materials.

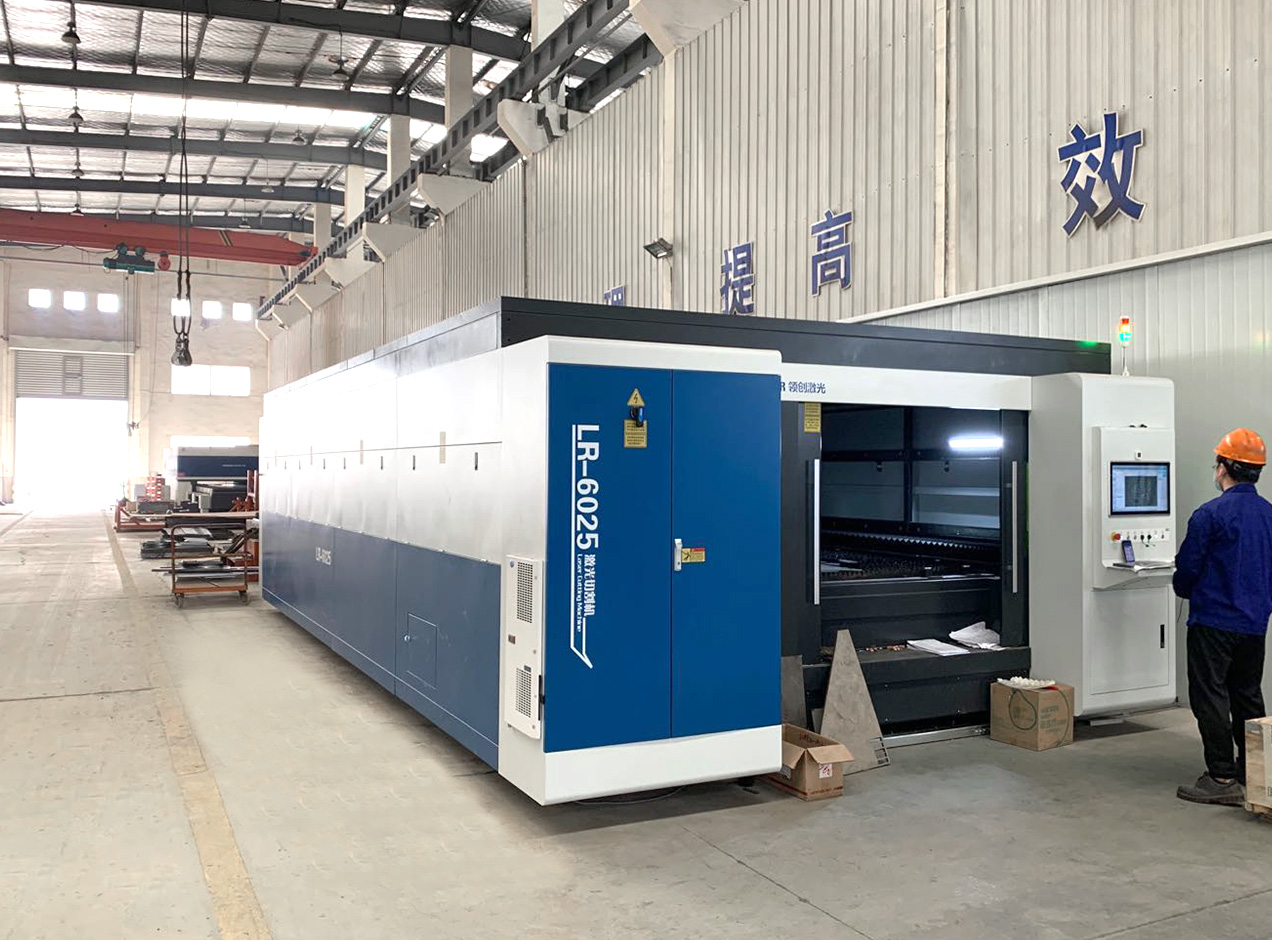

Steel plate welding structure is used in this series crusher and crusher rotor motor installed on the same base, the dowel pin coupling straight driving, rotor dynamic balance test, and can work backward operation have a safety interlock device to ensure that the operation can't open the door, when the rotor rotating inlet on the top of the grinder, can match with various forms of feeding mechanism, hammer for symmetry. This machine has simple structure, strong and durable, safe and reliable, easy to install, easy to operation and maintenance, small vibration, high productivity.

This series of crusher have two functions, coarse and fine crusher features suitable for fiber, fine material, high water material and fine crushing brittle materials. High output, low energy consumption.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com